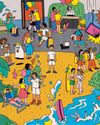

Three years after the Rana Plaza disaster, work conditions are still substandard—and garments even cheaper.

In April 2013, when the Rana Plaza building in Bangladesh crumbled and killed more than a thousand garment workers, Western clothing executives were chastened. They were the ones, after all, who’d been pressuring Bangladesh’s apparel factories to cheaply reproduce runway trends for consumers in the U.S. and Europe who’d grown used to $10 dresses. Following the accident, H&M, Zara, Walmart, Gap, and other major brands announced they’d fund and oversee factory inspections in Bangladesh, demanding improvements from facilities that fell short and cutting off business with those that didn’t get better. Bangladesh, with the help of the United Nations’ International Labour Organization (ILO), created its own inspection program and vowed to shut down unsafe facilities. Better vigilance, everyone figured, would be central to preventing similar accidents from happening again.

Three years have passed, and an uncomfortable truth is emerging: Vigilance isn’t enough. Factories in Bangladesh have improved, completing more than 60 percent of fixes required by the inspectors sent by clothing brands. Still, of some 1,600 factories covered by the Accord on Fire and Building Safety in Bangladesh, a major inspection program run by the brands, more than 80 percent are behind schedule on improvements. Factories in a smaller brand-organized program, the Alliance for Bangladesh Worker Safety, have also lagged. The government, too, has made limited progress: It’s shut down just 39 facilities that posed an “immediate” danger to workers. Meanwhile, the corporate and government investigators, along with outside organizations, keep finding defects: faulty sprinklers, exit stairwells used for storage, missing fire doors.

This story is from the October 31 - November 06 2016 edition of Bloomberg Businessweek.

Start your 7-day Magzter GOLD free trial to access thousands of curated premium stories, and 9,000+ magazines and newspapers.

Already a subscriber ? Sign In

This story is from the October 31 - November 06 2016 edition of Bloomberg Businessweek.

Start your 7-day Magzter GOLD free trial to access thousands of curated premium stories, and 9,000+ magazines and newspapers.

Already a subscriber? Sign In

Instagram's Founders Say It's Time for a New Social App

The rise of AI and the fall of Twitter could create opportunities for upstarts

Running in Circles

A subscription running shoe program aims to fight footwear waste

What I Learned Working at a Hawaiien Mega-Resort

Nine wild secrets from the staff at Turtle Bay, who have to manage everyone from haughty honeymooners to go-go-dancing golfers.

How Noma Will Blossom In Kyoto

The best restaurant in the world just began its second pop-up in Japan. Here's what's cooking

The Last-Mover Problem

A startup called Sennder is trying to bring an extremely tech-resistant industry into the age of apps

Tick Tock, TikTok

The US thinks the Chinese-owned social media app is a major national security risk. TikTok is running out of ways to avoid a ban

Cleaner Clothing Dye, Made From Bacteria

A UK company produces colors with less water than conventional methods and no toxic chemicals

Pumping Heat in Hamburg

The German port city plans to store hot water underground and bring it up to heat homes in the winter

Sustainability: Calamari's Climate Edge

Squid's ability to flourish in warmer waters makes it fitting for a diet for the changing environment

New Money, New Problems

In Naples, an influx of wealthy is displacing out-of-towners lower-income workers