Higher productivity and improvements in manufacturing efficiency can be ensured in many ways – investing in the right wire processing equipment is one of them. Fine tuning and optimising wire processing operations by installing the most up-to-date machinery can drive higher business revenues.

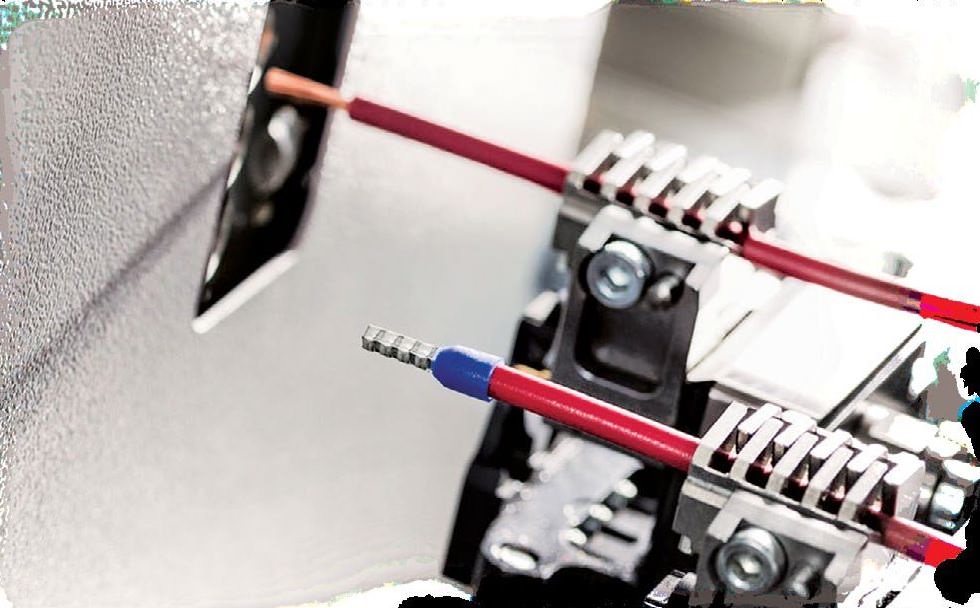

There are various wire processing machines designed specifically for particular wire processing operations like cutting, stripping, marking, crimping, seal insertion, twisting, etc. Some of these machines also have the capacity to perform a combination of different processes, e.g., one machine can be used for both cutting and stripping or for only cutting and only stripping, based on the mode that is required. These machines are available in manual, semi-automatic and fully automatic versions depending on the thickness of the wire.

Important trends in wire processing machinery

L. Sampath, director, EMST Marketing Pvt Ltd, says that cutting machines are the main equipment used in high-volume harness manufacturing. They cut the wire and strip the ends to the programmed length, and crimp the terminal.

“Though cutting machines have been around for decades, the current trend is to add more features to the machines mainly to monitor the quality of the wire processed,” says Sampath. He shares some of the features of wire processing machines that have become necessary for harness suppliers:

Cut and strip monitoring processes are predominantly driven by the use of new conducting materials (like aluminium) in the automotive segment. The requirements are to prevent angled cuts, prevent touching or damaging of single strands, prevent the cut-off of single or pulled strands, etc. Such requirements need new features to monitor the process through cameras or smart deduction systems.

Crimp monitoring systems have been an accepted standard since the 1990s but more stringent requirements are demanded on the degree of compression, tight crimping, height tolerances, pull strength, etc. Studying the crimp force for headroom as well as feasibility studies and reporting are becoming necessary.

This story is from the September 2018 edition of Electronics Bazaar.

Start your 7-day Magzter GOLD free trial to access thousands of curated premium stories, and 9,000+ magazines and newspapers.

Already a subscriber ? Sign In

This story is from the September 2018 edition of Electronics Bazaar.

Start your 7-day Magzter GOLD free trial to access thousands of curated premium stories, and 9,000+ magazines and newspapers.

Already a subscriber? Sign In