Lead has been traditionally used for making shot for centuries. While not nearly as abundant as many other metals, lead is easily mined and refined, and also relatively heavy, malleable and corrosion-resistant. Unfortunately, ingesting lead can be harmful to various organisms, including ducks and geese feeding in commonly hunted areas, the reason the U.S. Fish & Wildlife Service (USFWS) banned lead shot for waterfowl hunting in some areas in 1987, and made the ban nationwide in 1991.

The first and still primary substitute was steel. The grade used in shotshells weighs about one third less than typical lead shot, which makes steel shot less efficient when traveling through the air. Essentially, it has a lower “ballistic coefficient” than lead shot of the same size. Steel shot is so much harder than lead it patterns well in more open chokes than many waterfowlers traditionally used – and can actually damage tighter chokes, or even cause barrels on doubles to separate near the muzzles.

Many waterfowlers initially reported steel wounded too many birds, but some hunters used shot sizes based on their experience with lead. Experimentation proved steel could work pretty well when using one or two sizes larger, especially when started at higher muzzle velocities. Steel shot also took up more room inside a shotshell, the reason 10-gauge shotguns made a comeback after decades of declining use, and Federal introduced the 3½-inch 12-gauge case.

This story is from the February 2021 edition of Handloader.

Start your 7-day Magzter GOLD free trial to access thousands of curated premium stories, and 9,000+ magazines and newspapers.

Already a subscriber ? Sign In

This story is from the February 2021 edition of Handloader.

Start your 7-day Magzter GOLD free trial to access thousands of curated premium stories, and 9,000+ magazines and newspapers.

Already a subscriber? Sign In

OEHLER's New System 89 Chronograph

Measuring Bullet Performance Downrange

The Problem with Low Pressure Loads

Bullets & Brass

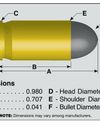

Measurements for Rifle Handloading

Handy Techniques for Accurate Ammunition

THE BRASS RING

In Range

Semi-custom Bullet Moulds

Mike's Shoot in' Shack

REVISITING THE 6.5 -06 A-SQUARE

Loading New Bullets and Powders

Cimarron Stainless Frontier .45 Colt

From the Hip

9x18mm Makarov

Cartridge Board

Alliant 20/28

Propellant Profiles

.224 Clark

Wildcat Cartridges