يحاول ذهب - حر

THE DIE IS CAST

March 2020

|Manufacturing Today

DIE AND MOULD MAKING IS REACHING NEW LEVELS IN INDIA WITH MODERN TECHNOLOGIES COMING IN

-

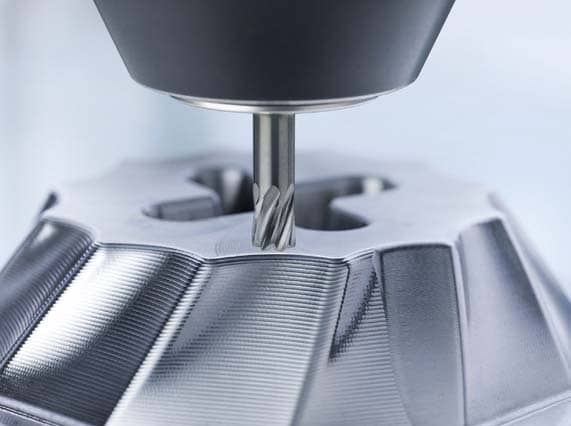

IT IS SAID TO BE THE BEGINNING OF manufacturing. The final product that a company ships out begins with a die and mould. Across industries that manufacture ‘solid’ products, it must have a die and mould. These vary based on the product, the component or sometimes even a minute part. The type of material that is used for making the mould depends upon the product that is going to be made with the mould.

More often than not, the die and mould making industry supply tools to companies from cross vertical domains such as automotive, aerospace, industrial machinery and heavy engineering, defence to consumer goods and electronics. In all the above, it is the automotive industry that is the largest source for die and moulds. Newer industries like aerospace and medical equipment are growing, but that is niche and little is spoken about that.

Ramakant Reddy, MD, LMT Tools India, says, “The major change in vehicle systems will be in the way it runs in the future. The diesel and petrol engines will be replaced in part by electric vehicles. This will reduce the need for hot forging dies for components like crankshaft, connecting rods, etc. To reduce body weight there would be more use of plastics & composites which again will have an effect on punching & pressing dies. With increased use of aluminium, plastics, and composites there will be more opportunities for injection moulding, die casting dies, etc. The die and mould manufacturers should adapt themselves to this change of requirement so that the bottom line is not affected.”

هذه القصة من طبعة March 2020 من Manufacturing Today.

اشترك في Magzter GOLD للوصول إلى آلاف القصص المتميزة المنسقة، وأكثر من 9000 مجلة وصحيفة.

هل أنت مشترك بالفعل؟ تسجيل الدخول

المزيد من القصص من Manufacturing Today

Manufacturing Today

Budget 2026-27: Emphasis on Indian manufacturing, MSMEs and clean mobility

Since we went to press just before the FM took the stage, we are showcasing the industry's wishlist here. For the full post-budget breakdown and reactions, head over to our website.

24 mins

February 2026

Manufacturing Today

India's indigenisation test

India's aerospace and defence indigenisation drive has moved beyond assembly towards deeper capability building, but persistent gaps in propulsion, certification, scale and execution will determine whether it delivers true strategic autonomy.

6 mins

February 2026

Manufacturing Today

Metaverse in Motion

India's manufacturers are leveraging AR/VR-powered industrial metaverse solutions, integrated with digital twins and IIoT, to accelerate workforce training, enhance maintenance efficiency, and scale enterprise-wide operational impact.

6 mins

February 2026

Manufacturing Today

MIC Electronics to deploy PIS across Salem Division

The total project value is Rs 56.43 lakh, encompassing equipment supply, installation, commissioning, and maintenance support.

1 min

February 2026

Manufacturing Today

Hindustan Zinc launches 'Zinc Moolya' for real-time pricing

The addition of 'Zinc Moolya' enhances VMB's capabilities by providing landed prices linked to the London Metal Exchange.

1 min

February 2026

Manufacturing Today

Adani, Embraer to assemble commercial aircraft in India

Embraer also anticipates a demand for at least 500 aircraft in the 80- to 146-seat category in India over the next two decades.

1 min

February 2026

Manufacturing Today

Machining by Data

India's machining industry is shifting from intuition-led practices to data-driven precision, using real-time machine data and Al to improve quality, productivity, and competitiveness.

7 mins

February 2026

Manufacturing Today

China+1 strategy: Decoupling myth or diversification reality

Are global manufacturers truly leaving China, or simply hedging their bets?

7 mins

February 2026

Manufacturing Today

From India's first crane to TIL 2.0: An 80-year legacy re-engineered

At 80, TIL Limited enters a new phase under Gainwell Group, blending engineering legacy with digital innovation to reemerge as a future-ready material handling solutions provider.

8 mins

February 2026

Manufacturing Today

AXISCADES partners with OGMA to boost aerospace MRO in India

Together, the companies will pursue joint market opportunities across India, the UAE, and the MENA region.

1 mins

February 2026

Translate

Change font size