Versuchen GOLD - Frei

GRINDING FLANGES AND JOURNALS SIMPLY AND PRECISELY

Manufacturing Today

|October 2020

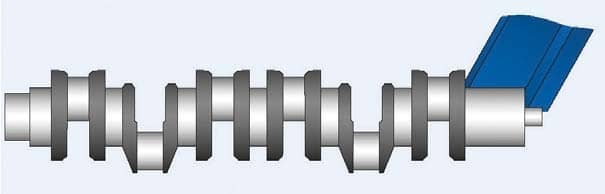

THE THYSSENKRUPP CRANKSHAFT COMPANY IN DANVILLE, IL, USES THE NUMERIKA GH1500 MACHINE FROM ZEMA TO GRIND THEIR CRANKSHAFTS. THE RELIABLE EXTERNAL GRINDING MACHINE WORKS IN A THREE-SHIFT OPERATION SEVEN DAYS A WEEK, GRINDING LF ANGE AND POST END ON HEAVY-DUTY CRANKSHAFTS.

-

CRANKSHAFT GRINDING WITH THE NUMERIKA GH 1500 CORUNDUM GRINDING MACHINE

THE NUMERIKA GH1500 CYLINDRICAL grinding machine reliably produces thyssenkrupp‘s crankshafts. The user-friendly control system, a torsion-resistant machine bed, hydrostatic guides and grinding spindles with hydrostatic bearings ensure ideal corundum grinding results. The user-friendly control system offers the required input screens for grinding with corundum.

thyssenkrupp Forged Technologies operates 17 locations in 8 different countries and is part of the thyssenkrupp AG headquartered in Essen, Germany. In his 21 years at thyssenkrupp, Process Engineering Manager Jose Fernando Dias de Moraes has been actively involved in several grinding projects at the company‘s production sites worldwide. His experiences with ZEMA Zscelica Ltda during his career have been very positive and valuable.

Dias de Moraes has been at the site in Danville, IL for four years now. Together with six other engineers, he oversees four production lines. The NUMERIKA GH1500 grinds crankshafts in three-shift operation seven days a week. The line, which mainly produces crankshafts for heavy-duty trucks and construction machinery from around the world, will expand with an additional NUMERIKA GH1500 by the end of this year.

Diese Geschichte stammt aus der October 2020-Ausgabe von Manufacturing Today.

Abonnieren Sie Magzter GOLD, um auf Tausende kuratierter Premium-Geschichten und über 9.000 Zeitschriften und Zeitungen zuzugreifen.

Sie sind bereits Abonnent? Anmelden

WEITERE GESCHICHTEN VON Manufacturing Today

Manufacturing Today

Could this common semiconductor become a game-changer for quantum chips?

Hyper-doped germanium shows superconductivity using standard semiconductor processes, opening a possible pathway for scalable quantum and cryogenic electronic applications.

1 mins

January 2026

Manufacturing Today

"We didn't chase scale, we built systems first”

Manish Jain, founder of Cilicant on how they built India's active packaging backbone from the shop floor up.

6 mins

January 2026

Manufacturing Today

Precision, People and Policy: Inside the shop floor powering Flex's Indian growth story

A visit to Flex's Chennai facility reveals how advanced technology, skilled talent and long-term commitment are helping India move from high-volume assembly to complex, globally competitive electronics manufacturing.

8 mins

January 2026

Manufacturing Today

Can India's auto supply chain keep pace with the industry's EV ambitions?

India's EV sector grows rapidly, but supply chain depth, component localisation, and critical minerals will determine global competitiveness.

4 mins

January 2026

Manufacturing Today

Cobots of the floor

Cobots are revolutionising warehouse operations by working safely alongside humans, boosting efficiency, scalability, and flexibility while addressing labour shortages in India's booming e-commerce sector.

6 mins

January 2026

Manufacturing Today

Tata Chemicals wins CII Grand Jury Award for R&D

This recognises its excellence in industry-academia research partnerships.

1 min

January 2026

Manufacturing Today

L&T secures major order for India's largest polyethylene unit

This facility will consist of two trains, each with a capacity of 575 KTPA, located in Bina, Madhya Pradesh.

1 min

January 2026

Manufacturing Today

Precision and Power

Suzlon Group's Manufacturing Business CEO Gurpratap Boparai on scaling smart manufacturing for India's wind energy future.

5 mins

January 2026

Manufacturing Today

Ola Electric rethinks the EV servicing model in India via Hyperservice

New Hyperservice Centres promise faster turnaround, digital transparency and same-day service at no extra cost.

1 min

January 2026

Manufacturing Today

From shop floor to global flight paths: GE Aerospace's Pune story

A decade of building aerospace capability in India

8 mins

January 2026

Translate

Change font size